- Time Ever in Indian Extrusion Industry

- 100% Molten Aluminium from NALCO

- No. 1 Product Quality That You Deserve

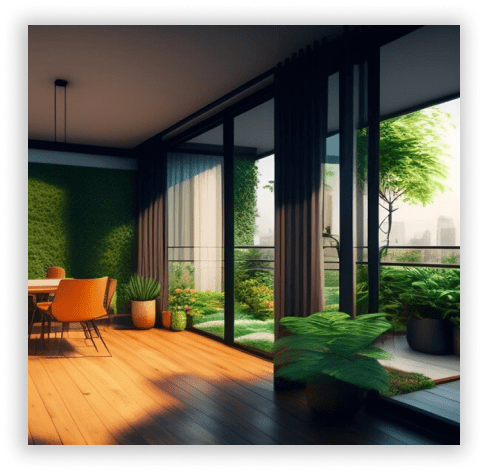

Building and Construction

Doors & Windows Profiles

Premium Architectural Profilles

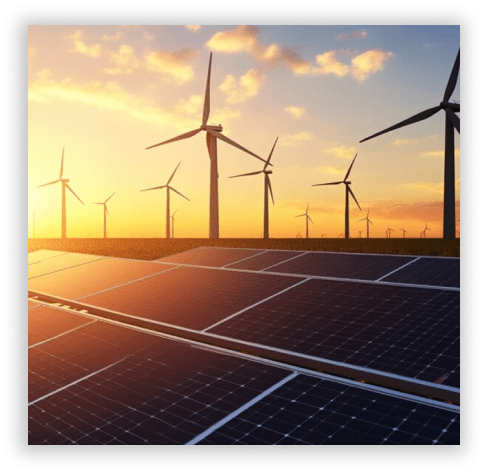

Renewable Energy

Solar Profiles

Wind Mill Profiles

Electrical and Electronics

Lighting & LED’s

IPS Tubes

Heat Sinks

Electrical Busbars

Trusted by 30,000 world-class brands and organizations of all sizes

About Dhaatu Fabex

We are an aluminium extrusion and value added product company

Dhaatu Fabex is an emerging producer of premium extruded aluminium products located in Angul Aluminium Park, Odisha. Driven by technocrats, we are equipped to deliver highly engineered solutions for the demanding sectors like industrial applications, renewable energy, aerospace and automotive. We also manufacture alloy billets, including hard and special alloys for extrusion.

Industry We Serve

Why Choose Us

Your Preferred Partner

At Dhaatu Fabex, we believe in bringing innovation to the industry and providing quality products to our customers. Our team of experienced professionals are dedicated to manufacture the best quality extruded aluminium products and in delivering them in the quickest time frame. We can customize your products according to the Customer’s requirement. We are committed in providing our Customers with superior quality aluminium products at competitive prices. Our products are manufactured with the highest quality materials and are built to last long. We use the latest technology to ensure our products meet the highest standards of quality. Our team of experienced engineers are always exploring new ways to make our products even better. We are always happy to help our Customers and make sure they are completely satisfied with their purchase. We are confident that you will be satisfied with our products and services.

Thank you for choosing Dhaatu Fabex – you’re trusted.

Our Facility

High-Capacity Extrusion

Leverage our cutting-edge machinery, including a 5-inch press with a remarkable 3000-ton annual capacity, ensuring swift and efficient production to meet large-scale demands. Strategic Location for Global Export

Capitalize on our strategic location in Angul, Orissa, near NALCO plant, facilitating to receive VIRGIN MOLTEN MATERIAL for seamless domestic and export processes. Benefit from efficient logistics, reducing lead times and enhancing our ability to serve international markets with agility.

Leverage our cutting-edge machinery, including a 5-inch press with a remarkable 3000-ton annual capacity, ensuring swift and efficient production to meet large-scale demands. Strategic Location for Global Export

Capitalize on our strategic location in Angul, Orissa, near NALCO plant, facilitating to receive VIRGIN MOLTEN MATERIAL for seamless domestic and export processes. Benefit from efficient logistics, reducing lead times and enhancing our ability to serve international markets with agility.

Our Approach

Deliver personalized solutions by understanding and responding to client needs, fostering strong and collaborative relationships.

Efficiency through Optimization

Drive operational excellence through continuous optimization, integrating lean principles and cutting-edge automation for heightened efficiency.

Advanced Design and Engineering

Lead with technological innovation, creating designs that redefine industry norms and elevate product performance.

Uncompromising Quality Standards

Uphold stringent quality control measures, ensuring compliance with industry regulations and certifications, and consistently delivering products of exceptional quality. We use Quality Controlled Forms, Safe Working Practices, and Operating Procedures to ensure we maintain the standards required to provide a first class product and service.

Efficiency through Optimization

Drive operational excellence through continuous optimization, integrating lean principles and cutting-edge automation for heightened efficiency.

Advanced Design and Engineering

Lead with technological innovation, creating designs that redefine industry norms and elevate product performance.

Uncompromising Quality Standards

Uphold stringent quality control measures, ensuring compliance with industry regulations and certifications, and consistently delivering products of exceptional quality. We use Quality Controlled Forms, Safe Working Practices, and Operating Procedures to ensure we maintain the standards required to provide a first class product and service.

Our Business Goals

We provide a greater range of alloys and have greater flexibility on profile design, tolerances, quantities and lead times than almost any other extruder. Our services are particularly helpful to customers developing new products and for industries where flexible quantities, tight tolerances and responsive, quick delivery are paramount.

Our Quality & Service

You can be sure of being supplied the highest quality of product, with every part of our manufacturing process being checked and inspected to ensure we meet your requirements. Provide intricate, systematic and diversified profiles. Uphold stringent quality control measures, ensuring compliance with industry regulations and certifications, and consistently delivering products of exceptional quality. Have a complete team for pre-sales and after-sales services.

• Our Inspection Processes Incorporate

• Precision measurement throughout the sequence of operations.

• Full batch traceability as standard.

• Tensile testing as required by the client

• Hardness testing - Webster and Rockwell.

• CMM - Coordinate Measuring Machine, if required

• Chemical Analysis and Mechanical Certification can be provided with your delivery.

• Our Inspection Processes Incorporate

• Precision measurement throughout the sequence of operations.

• Full batch traceability as standard.

• Tensile testing as required by the client

• Hardness testing - Webster and Rockwell.

• CMM - Coordinate Measuring Machine, if required

• Chemical Analysis and Mechanical Certification can be provided with your delivery.

Our Team

Mr. Koustav Bose

Founder & Managing DirectorKoustav is a Chemical Engineer from IGIT, Sarang, Odisha. Having worked in various roles for 16+ years in the Metal & Mining industry, he is passionate about the metal industry and believes in the significant socio-economic impact that it creates. His zeal to contribute directly in the industrial growth of Odisha along with the opportunity that aluminium downstream presents led him to the formation of DHAATU Fabex.

Mr. Joy Sinha

Co-Founder/Partner & Wholetime DirectorMr. Joy is a Mechanical engineer from Jadavpur University with Logistics and supply chain MDPs from IIM Kolkata and XLRI. He has 19 + years of experience in Metal, Mining and Petrochemical industry. His operational and supply chain expertise teamed with his leadership & management skill makes him an asset for the company. The growth opportunity that aluminium downstream industry presents motivated him to join DHAATU Fabex as Director.

Highly important to take into consideration a number of significant factors while looking for the top aluminium extrusion companies, including production capacity, quality requirements, and customization options. Dhaatu Fabex, a top extruded aluminium manufacturers, specializes in creating high-quality aluminum extrusion profiles with reliability and longevity. As an established Industrial aluminium providers and aluminium profile supplier, the company is well-known among industrial aluminum providers and offers a broad array of goods. Another well-known supplier of custom aluminum extrusion is Dhaatu Fabex, which offers tailored solutions to satisfy certain project needs.

Dhaatu Fabex is also a renowned custom aluminium extrusion supplier, providing bespoke solutions to meet specific project requirements.Known for its exceptional quality and innovation, it’s often considered the best aluminium company in India, catering to diverse sectors with its superior aluminium construction profiles and aluminium Extrusion Profiles. Whether for automotive, construction, or specialized industrial applications, Dhaatu Fabex ensures top-notch performance and reliability with its advanced aluminium extrusion capabilities.

Aluminum extrusion is a versatile manufacturing process that transforms aluminum alloy into objects with specific cross-sectional profiles through a highly controlled process. This involves heating an aluminum billet to a malleable state and then forcing it through a die to achieve the desired shape. The process allows for the creation of complex and intricate designs, making it invaluable in industries such as automotive, aerospace, construction, electronics, and consumer goods.

Aluminum’s versatile qualities allow for more visual alternatives and economical production, but it never compromises strength and durability. Although pure metal can be used in certain applications, like extrusion, it is more frequently combined with other metals to form alloys, which improve the already remarkable range of qualities of aluminum. This adaptability serves as the basis for the chaotic result that metal extrusion creates.

Leading Extruded Aluminium Manufacturers Revolutionizing the Industry

Highly important to take into consideration a number of significant factors while looking for the top aluminium extrusion companies, including production capacity, quality requirements, and customization options. Dhaatu Fabex, a top extruded aluminium manufacturers, specializes in creating high-quality aluminum extrusion profiles with reliability and longevity. As an established Industrial aluminium providers and aluminium profile supplier, the company is well-known among industrial aluminum providers and offers a broad array of goods. Another well-known supplier of custom aluminum extrusion is Dhaatu Fabex, which offers tailored solutions to satisfy certain project needs.

Dhaatu Fabex is also a renowned custom aluminium extrusion supplier, providing bespoke solutions to meet specific project requirements.Known for its exceptional quality and innovation, it’s often considered the best aluminium company in India, catering to diverse sectors with its superior aluminium construction profiles and aluminium Extrusion Profiles. Whether for automotive, construction, or specialized industrial applications, Dhaatu Fabex ensures top-notch performance and reliability with its advanced aluminium extrusion capabilities.

What is Aluminum Extrusion?

Aluminum extrusion is a versatile manufacturing process that transforms aluminum alloy into objects with specific cross-sectional profiles through a highly controlled process. This involves heating an aluminum billet to a malleable state and then forcing it through a die to achieve the desired shape. The process allows for the creation of complex and intricate designs, making it invaluable in industries such as automotive, aerospace, construction, electronics, and consumer goods.

The Benefits of Extrusion with Aluminum

Aluminum’s versatile qualities allow for more visual alternatives and economical production, but it never compromises strength and durability. Although pure metal can be used in certain applications, like extrusion, it is more frequently combined with other metals to form alloys, which improve the already remarkable range of qualities of aluminum. This adaptability serves as the basis for the chaotic result that metal extrusion creates.